VFD Control Panel in India

A VFD Control Panel (Variable Frequency Drive Control Panel) is an advanced electrical control system designed to regulate the speed and torque of electric motors by varying the frequency and voltage of the power supply. By integrating Variable Frequency Drives (VFDs) with control and protection components, these panels provide precise motor control, energy efficiency, and enhanced equipment longevity in industrial and commercial applications.

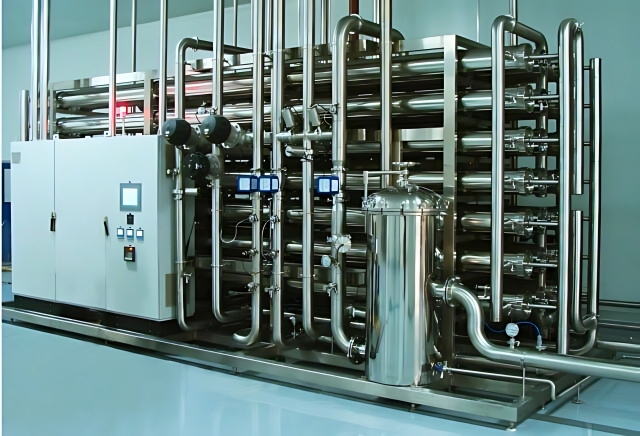

VFD Control Panels are essential for applications requiring variable speed control, such as pumps, fans, conveyors, and HVAC systems. They optimize energy consumption, reduce mechanical stress on motors, and improve process efficiency, making them ideal for industries like manufacturing, water treatment, oil and gas, and more. These panels are engineered for reliability, safety, and compliance with international standards.

- Precise Motor Control : VFDs enable adjustable speed and torque for optimal motor performance and process control.

- Energy Efficiency : Reduces power consumption by matching motor speed to load requirements, lowering operational costs.

- Modular Design : Compartmentalized structure for easy installation, maintenance, and scalability.

- Advanced Protection : Equipped with circuit breakers, overload relays, and harmonic filters to protect motors and electronics.

- User-Friendly Interface : Optional HMI or control switches for easy operation and real-time monitoring of motor parameters.

- IP-Rated Enclosures : Offers IP54 (indoor) or IP65 (outdoor) protection against dust, moisture, and harsh environments.

- High-Quality Construction : Built with 14/16 SWG CRCA sheets or stainless steel, powder-coated for corrosion resistance.

- Harmonic Mitigation : Includes detuned reactors or filters to reduce harmonic distortion caused by non-linear loads.

- Remote Monitoring (Optional): Supports IoT, SCADA, or PLC integration for remote control and diagnostics.

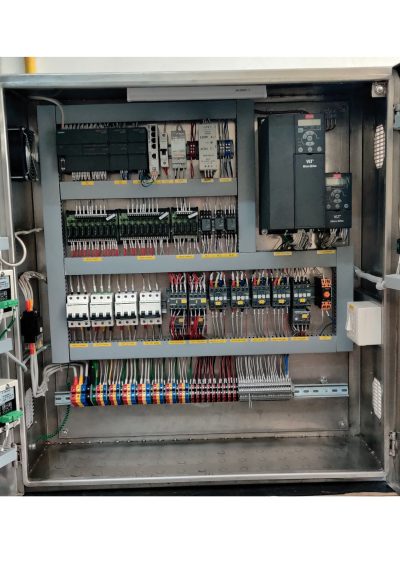

VFD Control Panels integrate various components to ensure precise motor control, system protection, and operational efficiency. Key components include:

- Variable Frequency Drive (VFD) : The core component that controls motor speed by adjusting frequency and voltage.

- Circuit Breakers (MCBs/MCCBs) : Protect the panel and connected motors from overloads and short circuits.

- Contactors : Enable switching of motor circuits for safe operation and maintenance.

- Overload Relays : Provide protection against motor overheating and excessive current.

- Harmonic Filters/Detuned Reactors (Optional): Mitigate harmonic distortion to protect equipment and comply with grid standards.

- Human-Machine Interface (HMI) (Optional): Touchscreen or keypad interface for monitoring and controlling VFD parameters.

- Busbars : High-conductivity copper or aluminum busbars for efficient power distribution.

- Surge Protection Devices (SPDs) : Safeguard against voltage surges caused by lightning or grid fluctuations.

- Wiring and Terminals : FRLS/HR FR insulated wires and DIN-rail or stud-type terminals for secure connections.

- Enclosure : Weatherproof, IP54/IP65-rated enclosure made of CRCA steel or stainless steel for durability.

| Parameter | Specification |

|---|---|

| Rated Voltage | 230V (Single-Phase) or 415V (3-Phase), 50/60 Hz (Customizable up to 690V) |

| Rated Power | 0.75 kW to 500 kW (Customizable) |

| Enclosure Material | 14/16 SWG CRCA Sheet or Stainless Steel, Powder-Coated |

| Degree of Protection | IP54 (Indoor), IP65 (Outdoor) |

| VFD Brands | Siemens, ABB, Schneider, Danfoss, or Custom |

| Control Modes | V/F Control, Vector Control, Sensorless Vector Control |

| Protection Devices | MCBs, MCCBs, Overload Relays, SPDs, Harmonic Filters |

| Communication Protocols | Modbus, Profibus, Ethernet, CANopen (Optional) |

| Surface Treatment | 7/9-Tank Powder Coating Process |

| Cable Entry | Top/Bottom, Gland-Type for Secure Terminations |

VFD Control Panels are critical for precise motor control and energy efficiency in various industries, including:

- Manufacturing Plants : Speed control for conveyors, mixers, and production machinery.

- Water Treatment Plants : Regulation of pumps and blowers for water and wastewater processes.

- HVAC Systems : Control of fans, compressors, and air handling units in commercial buildings.

- Oil and Gas : Management of pumps, compressors, and drilling equipment in refineries and pipelines.

- Cement and Mining : Speed control for crushers, conveyors, and heavy-duty motors.

- Food and Beverage : Automation of processing, packaging, and bottling equipment.

- Textile Industry : Control of spinning, weaving, and dyeing machines.

- Renewable Energy : Integration with solar or wind systems for efficient motor operation.

- Energy Savings : Optimizes motor speed to match load requirements, reducing power consumption by up to 30–50%.

- Extended Equipment Lifespan : Soft start/stop reduces mechanical stress on motors, extending their operational life.

- Precise Process Control : Adjustable speed and torque improve process accuracy and product quality.

- Reduced Maintenance : Minimizes wear and tear on motors and mechanical components, lowering maintenance costs.

- Harmonic Mitigation : Protects equipment and grid stability by reducing harmonic distortion.

- Scalability : Modular design supports additional VFDs or system expansions as needed.

- Cost-Effective : Lowers operational costs through energy efficiency and reduced downtime.

- Environmental Resilience : Weatherproof enclosures ensure reliable performance in harsh conditions.

As a leading VFD Control Panel manufacturer, we deliver high-quality, customized solutions to optimize your motor-driven processes. Here’s what sets us apart:

- Advanced Technology : Our panels feature industry-leading VFDs from trusted brands, ensuring precision and reliability.

- Tailored Solutions : We design panels to match your specific motor control needs, load requirements, and environmental conditions.

- Quality Assurance : All panels are CPRI type-tested and undergo rigorous quality checks for safety and performance.

- Expert Support : Our experienced engineers provide end-to-end support, from design and programming to installation and maintenance.

- Competitive Pricing : We offer cost-effective solutions without compromising on quality or functionality.

- Nationwide Reach : As a trusted electrical panel manufacturer in India , we ensure timely delivery and support across the country.