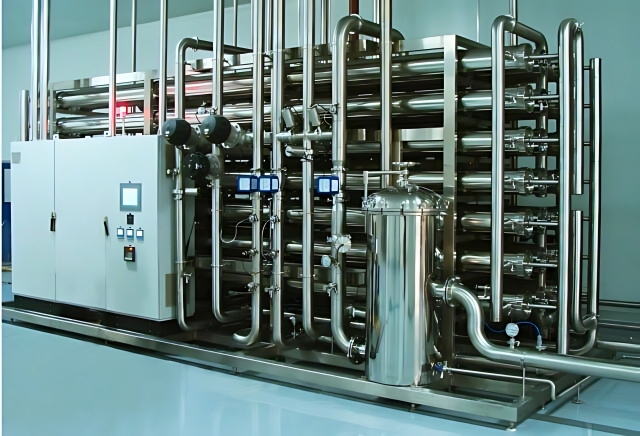

RO Control Panels in India

A PLC HMI RO Control Panel is an advanced automation solution that integrates a Programmable Logic Controller (PLC) with a Human-Machine Interface (HMI) to monitor, control, and optimize industrial processes and equipment. These panels serve as the central nervous system for automation, enabling precise control of machinery, real-time data visualization, and user-friendly interaction in industrial and commercial applications.

PLC HMI Control Panels are designed to enhance operational efficiency, improve system reliability, and reduce human intervention by automating complex processes. They are widely used in industries requiring high-precision control, such as manufacturing, oil and gas, water treatment, and pharmaceuticals. With robust construction and advanced technology, these panels ensure seamless operation, scalability, and compliance with industry standards.

- Automated Process Control : Manages filtration, chemical dosing, and cleaning cycles to ensure consistent production of purified water.

- Real-Time Monitoring : Tracks critical parameters like conductivity, pH, pressure, flow rate, and temperature via sensors and digital displays.

- PLC-Based Automation : Programmable Logic Controller (PLC) ensures precise control and seamless integration with SCADA or IoT systems.

- User-Friendly HMI (Optional): Touchscreen interface for intuitive operation, data visualization, and system diagnostics.

- Robust Protection : Equipped with circuit breakers, overload relays, and surge protectors to safeguard system components.

- IP-Rated Enclosures : Offers IP54 (indoor) or IP65 (outdoor) protection against dust, moisture, and harsh environments.

- High-Quality Construction : Built with 14/16 SWG CRCA sheets or stainless steel, powder-coated for corrosion resistance.

- Alarm and Fault Detection : Alerts operators to anomalies like high conductivity, low flow, or system faults for quick resolution.

- Customizable Configurations : Tailored to specific water purification system requirements, including RO, UF, and EDI capacities.

PLC HMI Control Panels are equipped with advanced components to ensure precise control, reliable operation, and user interaction. Key components include:

- Programmable Logic Controller (PLC) : The core processing unit that executes control logic for automated processes.

- Human-Machine Interface (HMI) : Touchscreen or display unit for operator interaction, data visualization, and system control.

- Circuit Breakers (MCBs/MCCBs) : Protect the panel and connected devices from overloads and short circuits.

- Power Supply Units : Provide stable power to PLC, HMI, and other components, typically 24V DC or 230V AC.

- Relays and Contactors : Facilitate switching of high-power devices based on PLC commands.

- Input/Output (I/O) Modules : Interface with sensors, actuators, and other field devices for data acquisition and control.

- Surge Protection Devices (SPDs) : Safeguard against voltage surges and transients.

- Communication Modules : Support protocols like Modbus, Profibus, Ethernet, or OPC for integration with other systems.

- Wiring and Terminals : FRLS/HR FR insulated wires and DIN-rail terminals for secure and reliable connections.

- Enclosure : Weatherproof, IP54/IP65-rated enclosure made of CRCA steel or stainless steel for durability.

| Parameter | Specification |

|---|---|

| Rated Voltage | 230V (Single-Phase) or 415V (3-Phase), 50/60 Hz; 24V DC for PLC/HMI |

| Rated Current | 10A to 400A (Customizable) |

| Enclosure Material | 14/16 SWG CRCA Sheet or Stainless Steel, Powder-Coated |

| Degree of Protection | IP54 (Indoor), IP65 (Outdoor) |

| PLC Type | Modular/Compact PLC (Customizable) |

| HMI Type | Touchscreen or Keypad-Based, 4″ to 15″ Display (Customizable) |

| Communication Protocols | Modbus, Profibus, Ethernet, OPC UA, etc. |

| Protection Devices | MCBs, MCCBs, SPDs, EMI Filters |

| Standards Compliance | IEC 61439, IS 8623, CPRI Type-Tested |

| Surface Treatment | 7/9-Tank Powder Coating Process |

| Cable Entry | Top/Bottom, Gland-Type for Secure Terminations |

PLC HMI Control Panels are essential for automation and control in a wide range of industries, including:

- Manufacturing Plants : Automation of production lines, conveyors, and robotic systems.

- Oil and Gas : Control of pumps, valves, and drilling equipment in refineries and pipelines.

- Water Treatment Plants : Management of pumps, filters, and chemical dosing systems.

- Pharmaceuticals : Precise control of mixing, packaging, and cleanroom processes.

- Food and Beverage : Automation of processing, bottling, and packaging lines.

- HVAC Systems : Control of heating, ventilation, and air conditioning systems in commercial buildings.

- Power Plants : Monitoring and control of turbines, generators, and auxiliary systems.

- Smart Buildings : Integration with building management systems (BMS) for lighting, security, and energy management.

- Enhanced Automation : Streamlines complex processes, reducing manual intervention and improving efficiency.

- Real-Time Monitoring : Provides live data and diagnostics for quick decision-making and issue resolution.

- Improved Productivity : Optimizes process control, minimizing downtime and maximizing output.

- User-Friendly Interface : Intuitive HMI screens simplify operation for operators and technicians.

- Scalability : Modular design supports integration with additional devices or systems as needs evolve.

- Reliable Operation : Robust protection and high-quality components ensure uninterrupted performance.

- Cost-Effective : Reduces operational costs through automation, energy efficiency, and minimal maintenance.

As a leading PLC HMI Control Panel manufacturer , we deliver high-quality, customized automation solutions to meet your specific needs. Here’s what sets us apart:

- Advanced Technology : Our panels feature industry-leading PLCs and HMIs from trusted brands, ensuring precision and reliability.

- Tailored Solutions : We design panels to match your specific process requirements, environmental conditions, and integration needs.

- Quality Assurance : All panels are CPRI type-tested and undergo rigorous quality checks for safety and performance.

- Expert Support : Our experienced engineers provide end-to-end support, from system design and programming to installation and maintenance.

- Competitive Pricing : We offer cost-effective solutions without compromising on quality or functionality.

- Nationwide Reach : As a trusted electrical panel manufacturer in India , we ensure timely delivery and support across the country.