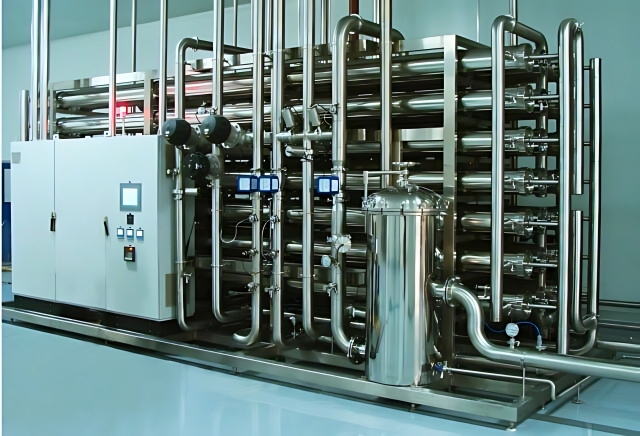

A Pressure Boosting Panel is an advanced electrical control system designed to manage and optimize the operation of pressure boosting systems, which are used to maintain consistent water pressure in water supply networks. These panels control multiple pumps to deliver adequate water pressure for applications in residential, commercial, industrial, and municipal settings, ensuring reliable water distribution even in high-demand or multi-story environments.

The Pressure Boosting Panel integrates intelligent control mechanisms, such as PLCs or VFDs, to automate pump operation, monitor system parameters, and ensure energy-efficient performance. Engineered for reliability, safety, and ease of use, these panels are essential for maintaining stable water pressure, reducing energy consumption, and extending the lifespan of pumping systems.

- Automated Pump Control : Manages multiple pumps to maintain consistent water pressure based on demand.

- Variable Frequency Drive (VFD) Integration : Optimizes pump speed for energy efficiency and precise pressure control.

- Real-Time Monitoring : Monitors pressure, flow rate, and system status through sensors and digital displays.

- PLC-Based Automation : Programmable Logic Controller (PLC) ensures precise control and seamless integration with SCADA or IoT systems.

- User-Friendly HMI (Optional): Human-Machine Interface with touchscreen display for intuitive operation and data visualization.

- Robust Protection : Equipped with circuit breakers, overload relays, and surge protectors to safeguard pumps and electronics.

- IP-Rated Enclosures : Offers IP54 (indoor) or IP65 (outdoor) protection against dust, moisture, and harsh environmental conditions.

- High-Quality Construction : Built with 14/16 SWG CRCA sheets or stainless steel, powder-coated for corrosion resistance.

- Energy Efficiency : Reduces power consumption by optimizing pump operation and minimizing unnecessary runtime.

Pressure Boosting Panels are equipped with advanced components to ensure efficient pump control, system protection, and reliable operation. Key components include:

- Programmable Logic Controller (PLC) : Executes control logic for automated pump operation and system monitoring.

- Variable Frequency Drive (VFD) : Regulates pump speed to maintain consistent pressure and optimize energy usage.

- Human-Machine Interface (HMI) (Optional): Touchscreen or keypad display for operator interaction and real-time data monitoring.

- Circuit Breakers (MCBs/MCCBs) : Protect the panel and pumps from overloads and short circuits.

- Pressure Sensors/Transmitters : Measure water pressure and provide feedback for precise control.

- Flow Sensors (Optional): Monitor water flow rates to optimize system performance.

- Relays and Contactors : Control pump switching and ensure safe operation.

- Surge Protection Devices (SPDs) : Safeguard against voltage surges caused by lightning or grid fluctuations.

- Wiring and Terminals : FRLS/HR FR insulated wires and DIN-rail or stud-type terminals for secure connections.

- Enclosure : Weatherproof, IP54/IP65-rated enclosure made of CRCA steel or stainless steel for durability.

| Parameter | Specification |

|---|---|

| Rated Voltage | 230V (Single-Phase) or 415V (3-Phase), 50/60 Hz; 24V DC for PLC/HMI |

| Rated Current | 10A to 400A (Customizable) |

| Enclosure Material | 14/16 SWG CRCA Sheet or Stainless Steel, Powder-Coated |

| Degree of Protection | IP54 (Indoor), IP65 (Outdoor) |

| PLC Type | Modular/Compact PLC (Brands: Siemens, Allen-Bradley, Mitsubishi, or Custom) |

| VFD Brands | Siemens, ABB, Schneider, Danfoss, or Custom |

| HMI Type | Touchscreen, 4″ to 15″ Display (Optional) |

| Sensors | Pressure, Flow, Level Sensors (Customizable) |

| Communication Protocols | Modbus, Profibus, Ethernet, OPC UA (Optional) |

| Protection Devices | MCBs, MCCBs, SPDs, Overload Relays |

| Surface Treatment | 7/9-Tank Powder Coating Process |

| Cable Entry | Top/Bottom, Gland-Type for Secure Terminations |

Pressure Boosting Panels are critical for maintaining consistent water pressure in a variety of applications, including:

- Residential Complexes : Ensuring adequate water pressure for apartments, villas, and high-rise buildings.

- Commercial Buildings : Supplying water for offices, shopping malls, hotels, and HVAC systems.

- Industrial Facilities : Managing water pressure for manufacturing processes, cooling systems, and equipment cleaning.

- Municipal Water Supply : Boosting water pressure in urban and rural water distribution networks.

- Hospitals : Providing reliable water pressure for medical facilities and equipment.

- Firefighting Systems : Controlling high-pressure pumps for fire suppression systems.

- Irrigation Systems : Maintaining pressure for agricultural and landscaping irrigation.

- Water Treatment Plants : Supporting water distribution in treatment and purification processes.

- Consistent Water Pressure : Ensures stable water pressure for all connected systems, regardless of demand fluctuations.

- Energy Efficiency : VFDs and intelligent controls reduce power consumption by optimizing pump operation.

- Real-Time Monitoring : Provides live data on pressure, flow, and system status for quick diagnostics and maintenance.

- Extended Pump Lifespan : Soft start/stop and variable speed control reduce mechanical stress on pumps.

- Low Maintenance : Modular design and high-quality components minimize downtime and maintenance costs.

- Scalability : Supports additional pumps or sensors for system expansions as needed.

- Cost-Effective : Reduces operational costs through energy savings and reliable performance.

- Environmental Resilience : Weatherproof enclosures ensure reliable operation in harsh outdoor conditions.

As a leading Pressure Boosting Panel manufacturer , we deliver high-quality, customized solutions to optimize your water pressure systems. Here’s what sets us apart:

- Advanced Technology : Our panels feature industry-leading PLCs, VFDs, and HMIs for precise control and reliability.

- Tailored Solutions : We design panels to match your specific pressure requirements, pump configurations, and environmental conditions.

- Quality Assurance : All panels are CPRI type-tested and undergo rigorous quality checks for safety and performance.

- Expert Support : Our experienced engineers provide end-to-end support, from system design and programming to installation and maintenance.

- Competitive Pricing : We offer cost-effective solutions without compromising on quality or functionality.

- Nationwide Reach : As a trusted electrical panel manufacturer in India , we ensure timely delivery and support across the country.