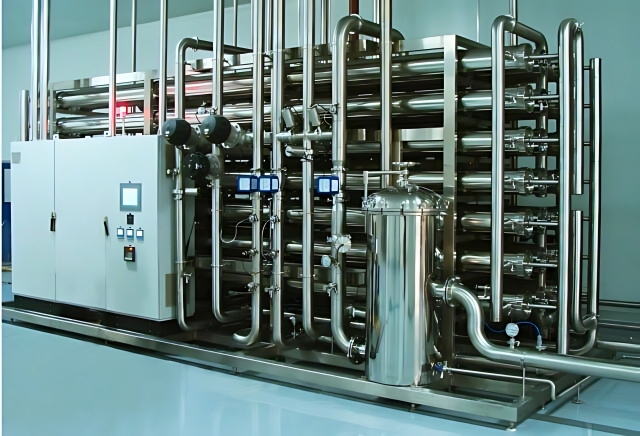

Control Panel for Hot Water Sanitization Systems

A Control Panel for Hot Water Sanitization System is a specialized automation system designed to manage and optimize the operation of hot water sanitization systems used for disinfection and sterilization in various industries. These panels control critical components such as heaters, pumps, valves, and sensors to maintain precise water temperature, flow, and circulation, ensuring effective sanitization while meeting stringent hygiene standards.

Equipped with advanced control technologies like Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs), these panels provide automated operation, real-time monitoring, and precise control of sanitization processes. They are essential for industries requiring high levels of cleanliness, such as pharmaceuticals, food and beverage, and healthcare, ensuring compliance with regulatory standards and enhancing operational efficiency.

- Precise Temperature Control : Maintains consistent water temperature for effective sanitization, typically between 70°C and 85°C.

- Automated Operation : PLC-based control automates heating, circulation, and valve operations, reducing manual intervention.

- Real-Time Monitoring : Monitors critical parameters like temperature, pressure, and flow rate through sensors and digital displays.

- User-Friendly HMI (Optional): Touchscreen interface for intuitive operation and real-time data visualization.

- Robust Protection : Equipped with circuit breakers, overload relays, and surge protectors to safeguard system components.

- IP-Rated Enclosures : Offers IP54 (indoor) or IP65 (outdoor) protection against dust, moisture, and harsh environments.

- High-Quality Construction : Built with 14/16 SWG CRCA sheets or stainless steel, powder-coated for corrosion resistance.

- Alarm and Fault Detection : Alerts operators to anomalies like temperature deviations or pump failures for quick resolution.

- Customizable Configurations : Tailored to specific sanitization system requirements, including heater and pump capacities.

Control Panels for Hot Water Sanitization Systems are equipped with advanced components to ensure efficient control, monitoring, and protection. Key components include:

- Programmable Logic Controller (PLC) : Executes control logic for automated operation of heaters, pumps, and valves.

- Human-Machine Interface (HMI) (Optional): Touchscreen or keypad display for operator interaction and real-time monitoring of system parameters.

- Temperature Sensors/RTDs : Measure water temperature to ensure precise sanitization conditions.

- Pressure and Flow Sensors : Monitor system pressure and water flow for optimal performance.

- Circuit Breakers (MCBs/MCCBs) : Protect the panel and connected equipment from overloads and short circuits.

- Relays and Contactors : Control heaters, pumps, and valves based on PLC commands.

- Power Supply Units : Provide stable power (typically 24V DC or 230V AC) to PLC, HMI, and other components.

- Surge Protection Devices (SPDs) : Safeguard against voltage surges caused by lightning or grid fluctuations.

- Wiring and Terminals : FRLS/HR FR insulated wires and DIN-rail or stud-type terminals for secure connections.

- Enclosure : Weatherproof, IP54/IP65-rated enclosure made of CRCA steel or stainless steel for durability in harsh environments.

| Parameter | Specification |

|---|---|

| Rated Voltage | 230V (Single-Phase) or 415V (3-Phase), 50/60 Hz; 24V DC for PLC/HMI |

| Rated Current | 10A to 200A (Customizable) |

| Enclosure Material | 14/16 SWG CRCA Sheet or Stainless Steel, Powder-Coated |

| Degree of Protection | IP54 (Indoor), IP65 (Outdoor) |

| PLC Type | Modular/Compact PLC (Customizable) |

| HMI Type | Touchscreen, 4″ to 15″ Display (Customizable) |

| Sensors | Temperature (RTD/Thermocouple), Pressure, Flow Sensors |

| Communication Protocols | Modbus, Profibus, Ethernet, OPC UA (Optional) |

| Protection Devices | MCBs, MCCBs, SPDs, Overload Relays |

| Temperature Control Range | 70°C to 85°C (Customizable) |

| Surface Treatment | 7/9-Tank Powder Coating Process |

| Cable Entry | Top/Bottom, Gland-Type for Secure Terminations |

Control Panels for Hot Water Sanitization Systems are critical for maintaining hygiene and compliance in industries requiring sterile water, including:

- Pharmaceuticals : Sanitization of equipment, pipelines, and cleanrooms to meet GMP standards.

- Food and Beverage : Cleaning and sterilization of processing equipment, tanks, and bottling lines.

- Hospitals and Healthcare : Hot water sanitization for surgical instruments, medical equipment, and sterile environments.

- Laboratories : Sterilization of lab equipment and water systems for research and testing.

- Dairy Industry : Sanitization of milking systems, storage tanks, and processing lines.

- Breweries : Cleaning of brewing equipment and pipelines to ensure product quality.

- Chemical Industries : Sanitization of reactors and processing equipment for contamination-free production.